Homemade Key Cutting Machine

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 20 Days |

| Packaging: | Steel Box |

|---|---|

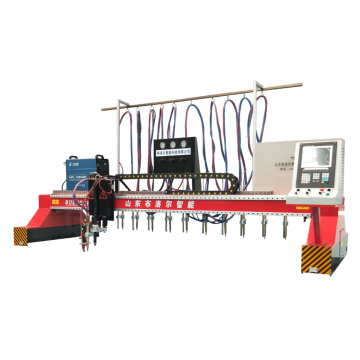

| Brand: | Buluoer |

| Transportation: | Ocean |

| Place of Origin: | Ji'nan City, Shandong Province, China |

| Certificate: | ISO9001 |

| Port: | Qingdao Port |

Basic Info

Model No.: BLZT-4080

Click on the follow link to find out more information: https://www.buluoercuttingmachine.com/carbon-steel-plate-cutting-machine/

Company Info

- Company Name: Shandong Buluoer Intelligent Technology Co., Ltd.

- Representative: Jing Fengquan

- Product/Service: Fiber Laser Cutting Machine , Flame Cutting Machine , Metal Cutting Machine , CNC Plasma Cutting Machine , Gantry CNC Cutting Machine , CNC Fiber Laser Cutter

- Capital (Million US $): 110 Million

- Year Established: 2014

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 11% - 20%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No. 666 Fengnian Av., Mingshui Economic Zone, Zhangqiu District, Ji'nan City, Shandong Province

- Contact Person: Ms. Alisa Yu

- Tel: 0531-18668937296

Premium Related Products

Other Products

Hot Products

FORST Industrail Galvanized Filter Cartridge End CapFORST Galvanized Steel Filter Bag CageFORST Replacing Torit Air Compressor Filter CartridgeFORST Coal Dust Collector EquipmentFORST Pleated Polyester HEPA Filters BagFORST Cylinder Air Dust Remover Filter CartridgeFilter Cartridge Vacuum Dust ExtractorForst Spray Booth Fiberglass FilterSFFX-3X Industrial Dust Collector SystemSFFX-X Cartridge Filter Dust Collector SystemSquare Flange Air Filter CartridgeForst Gas Turbine Intake Air Filter CartridgeFORST Air Filter Element AssyAir Filter Cartridge,Air Cartridge Filter,Air Filter ElementPleated Bag Filters, Washable Bag Filters, Bag Filters For Cement DustIndustrial Air Filter Dust Collector Filter Cartridge

Quality Choice